Indi Conveyor Belt for Lightweight Cardboard

What is Indi?

The Indi range offers 3 types of conveyor belts: Lift & Grip, Carton, Cotton.

This type of belt is primarily used for the short transportation of light goods and cardboard boxes.

This belt is applied in the postal, pharmaceutical, and grocery store industries. Sometimes, even distribution centers will have this type of conveyor to move packages within their warehouses.

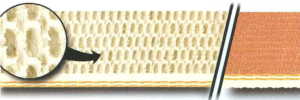

Lift & Grip are multi-ply rubber belts with a honeycomb pattern on the top cover designed to convey items on a steep incline, the bottom side is bare without rubber coating. Two types of cover pattern are available. Lift has a cellular honeycomb pattern and Grip has a woven honeycomb pattern. Both covers are available in a choice of coatings; Black A, Black G, Beige.

- Belts A are suitable for conveying standard items such as bags, boxes, tins.

- Belts G are suitable for conveying oily items including metal sheets and manufacturing components.

- Beige belts are suitable for conveying clean items including pharmaceuticals and perfume.

|

LIFT A / LIFT G |

LIFT BEIGE |

GRIP A / GRIP G |

Fat resistance |

Strength |

Number of plies |

Total thickness |

Thick-ness covers |

Abrasive index |

Temperature range |

Hardness Shore A |

|

| LIFT G | Medium / MOR |

250/N/mm 400 N/mm |

2 plies 3 plies |

6 mm 7 mm |

3 mm |

<5.5″ <140mmᶟ |

-4° to 158°F -20°C to 70°C |

60 |

| GRIP G | Medium / MOR |

250/N/mm 400 N/mm |

2 plies 3 plies |

5.8 mm 6.8 mm |

3 mm |

<5.5″ <140mmᶟ |

-4° to 158°F -20°C to 70°C |

60 |

| LIFT A | – |

250/N/mm 400 N/mm |

2 plies 3 plies |

6 mm 7 mm |

3 mm |

<6″ <150mmᶟ |

-4° to 158°F -20°C to 70°C | 60 |

| LIFT G | – |

250/N/mm 400 N/mm |

2 plies 3 plies |

5.8 mm 6.8 mm |

3 mm |

<6″ <150mmᶟ |

-4° to 158°F -20°C to 70°C |

50 |

| LIFT BEIGE | – |

250/N/mm 400 N/mm |

2 plies 3 plies |

6 mm 7 mm |

<6″ <150mmᶟ |

-4° to 158°F -20°C to 70°C | 50 |

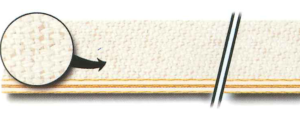

Carton belts for the cardboard industry.

Carton belts for the cardboard industry.

The carcass is made of 3 cotton/polyester plies separated by rubber interlayer’s. The top cover is coated with a clear non-slip rubber that avoids marking the items being carried. The bottom cover has a coating designed to enable free running on idlers or on a slide bed.

| Type of fabrics | Strength | Number of plies | Total thickness | Cover thickness | Abravise index | Temperature range | Hardness Shore A | |

| CARTON | Coton / polyester | 200 N/mm | 3 plies | 7 mm | 3 mm |

<2.7″ <70 mmᶟ |

-4° to 158°F -20°C to 70°C |

60 |

Cotton- Belts for the rubber industry.

Cotton belts have 3, 4 or 5 cotton plies, with no interlayer’s. Depending on the type of use these belts can be coated in either beige or red rubber covers (C=0.5mm cover), or stay bare (B = bare).

Cotton range belts are usually used to convey crude or vulcanised rubber pieces.

- Cotton C+C = 0.5mm red rubber cover, with a rubber coated bottom cover. This belt is used in numerous industries, its main benefit being its dense structure enabling a high resistance to fastening while being a lightweight belt.

- Cotton B+B= Beige belt without covers. Used in the tyre industry to handle crude rubber in cold to average temperatures

|

COTTON C+C |

COTTON B+B |

| Type of fabrics | Strength | Number of plies | Total thickness | Cover thickness | Abrasive index | Temperature range | Hardness Shore A | |

| COTTON C+C | Coton / polyester | 80 N/mm |

3 plies 4 plies 5 plies |

3.5 mm 4.8 mm 6 mm |

0.5 mm | -20°C to 70°C | 60 | |

| COTTON B+B | Coton / polyester | 80 N/mm | 3 plies | 7 mm | without covers | -20°C to 70°C | 60 |