Mechanical Fasteners

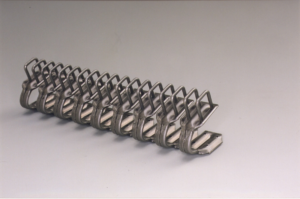

Connecting Pins

Cobra America offers a full line of connecting pins:

Cobra America offers a full line of connecting pins:

• Standard Stainless Steel Connecting Pins

• Armored Stainless Steel Connecting Pins

• Nylon Armored Coated Connecting Pins

• Galvanized Connecting Pins

• Galvanized Connecting Zip Pins

• Hardfield Stainless Steel Polycoated Pins

Our Connecting Pins range in sizes from 5mm to 9mm in diameter and up to 60″ in length.

Custom sizes are available upon request.

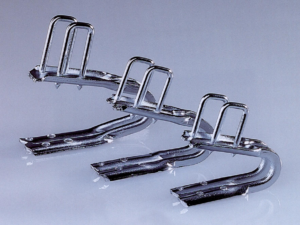

Goro Fasteners

- Goro Titan 05

- Goro 2001

- Goro 20002

- Goro 20003

- Goro TITAN T14

- Goro TITAN T12

- Goro TITAN T10

- Goro RECORD V6 (RV6)

Heavy Duty hinged belt fasteners suitable for round baler belts.

Heavy Duty hinged belt fasteners suitable for round baler belts.- Fasteners and staples in stainless steel.

- The fastener is particularly suitable for use in extreme crop conditions such as silage or high density hay baling.

- Flexible stainless steel polymer covered cable or rigid stainless connecting pin. Replacement connecting pins are available and should be replaced every 750 to 1000 bales.

|

Belt Thickness Range |

Max Working Belt Tension |

Pin Diameter |

Min Pulley Diameter |

||||

| Inch | mm | PIW | N/mm | Inch | mm | Inch | mm |

| 3/16-9/32 | 5-7 | 360 | 65 | 1/8 | 3 | 3 3/16 | 80 |

This series is available in anti-magnetic stainless steel which is recommended for the food related industries (types 0-15), and carbon coated steel (type 20-65).

This series is available in anti-magnetic stainless steel which is recommended for the food related industries (types 0-15), and carbon coated steel (type 20-65).- The fastener is manufactured from a flat steel strip which produces a flat, low profile belt joint as well as a high tensile strength.

- This series has a short reach into the belt making it suitable for applications with small pulleys

| Size |

Belt Thickness |

Minimum Pulley |

Belt Working Tension |

|||

| Inches | mm | Inches | mm | PIW | kN/m | |

| n°0 | Up to 1/16” | Up to 1.5 | 1” | 25mm | 25 | 4.3 |

| n°1 | 1/16” to 3/32” | 1.5 to 2.5 mm | 1 ½” | 40mm | 45 | 4.8 |

| n°7 | 3/32” to 9/64” | 2.5 to 3.5 mm | 2” | 50mm | 50 | 8.7 |

| n°15 | 1/8” to 5/32” | 3 to 4 mm | 2 ½” | 65mm | 65 | 11.4 |

| n°20 | 5/32” to 3/16” | 4 to 5 mm | 3” | 75mm | 95 | 16.6 |

| n°25 | 3/16” to 15/64” | 5 to 6 mm | 4” | 100mm | 100 | 17.5 |

| n°27 | 15/64” to 9/32” | 6 to 7 mm | 5” | 130mm | 120 | 21.0 |

| n°35 | 9/32” to 5/16” | 7 to 8 mm | 7” | 180mm | 150 | 26.0 |

| n°45 | 5/16” to 3/8” | 8 to 9.5 mm | 9” | 230mm | 165 | 28.0 |

| n°55 | 3/8” to 7/16” | 9.5 to 11 mm | 12” | 300mm | 175 | 30.0 |

| n°65 | 7/16” to ½” | 11 to 12.5 mm | 14” | 360mm | 200 | 35.0 |

Solid Strip Fastener: One complete strip is installed on the belt across the full width preventing loss or damage during transportation and storage.

Solid Strip Fastener: One complete strip is installed on the belt across the full width preventing loss or damage during transportation and storage.- High Joint Strength: The staggered arrangement of the staples enables a splice with a high tensile and dynamic strength to be installed. The loads are spread across the staggered staple arrangement.

- Joint Alignment: The fasteners are installed with the hammer tool. Install the fastener on either side and in the center of the splice ensuring the fasteners are square to the belt and then install the fasteners across the full width. Because of the good alignment, it is very easy for the connecting pin to be inserted.

- Less Impact Force: The front edge of the fastener is chambered which decreases the impact and wear to idlers, pulleys, and cleaners during the running of the conveyor.

- Pin Life: The loop section of the fastener is designed to maintain a good even radius after the fastener is clinched, thus providing a good working surface for the connecting pin to interact with.

- Application: Heavy-Duty conveyor belt, underground mining, main haulage, coal, potash.

|

Staple Size |

Belt Thickness Range |

Max Breaking Tension of Belt |

Max Working Tension |

Min Pulley Diameter |

|||

|

NO. |

Inch |

mm |

PIW |

mm |

PIW |

Inch |

mm |

|

22 |

19/64” – 11/32” |

7.5 – 9 |

10,000 |

1750 |

1200 |

16 |

400 |

|

24 |

11/32” – 13/32” |

9 – 11 |

|||||

|

26 |

13/32” – 1/2 “ |

11 – 13 |

|||||

|

28 |

1/2” – 19/32” |

13 – 15 |

|||||

Solid Strip Fastener: One complete strip is installed on the belt across the full width preventing loss or damage during transportation and storage.

Solid Strip Fastener: One complete strip is installed on the belt across the full width preventing loss or damage during transportation and storage.- High Joint Tensile Strength: The unique method of bending the staples during installation and the reach of the fastener into the belt gives the joint an exceptionally high tensile strength while maintaining excellent dynamic characteristics.

- Joint Alignment: The fasteners are installed with either the hammer tool or an operated (Pneumatic or Hydraulic) tool. Install the fastener on either side and in the center of the splice ensuring the fasteners are square to the belt and then install the fasteners across the full width. Because of the good alignment, it is very easy for the connecting pin to be inserted.

- Less Impact Force: The front edge of the fastener is chamfered which decreases the impact and wear to idlers, pulleys, and cleaners during the running of the conveyor.

- Pin Life: The loop section of the fastener is designed to maintain a good even radius after the fastener is clinched, thus providing a good working surface for the connecting pin to interact with.

- Application: Heavy-Duty conveyor belt, underground mining, main haulage, coal, potash.

|

Staple Size |

Belt Thickness Range |

Max Breaking Tension of Belt |

Max Working Tension |

Min Pulley Diameter |

|||

|

NO. |

Inch |

mm |

PIW |

mm |

PIW |

Inch |

mm |

|

29 |

13/32” – 9/16” |

10 – 14 |

20,000 |

3500 |

2000 |

20 |

500 |

|

33 |

9/16” – 23/32” |

14 – 18 |

|||||

Twin Staple Fastener

Twin Staple Fastener- Good for the deep trough belt whose troughing angle is 45 degrees

- Staggered Staples to maximize the fastener holding

- Complete range for the belt thickness of 8-16mm

- Made of high strength steel: the strength rigidity and wear resstance of the fasteners are guaranteed.

- The staggered arrangement of the staples enables a splice with a high tensile and dynamic strength to be installed. The loads are spread across the staggered staple arrangement.

- The joints have a high strength and long life.

- Applications: Underground and surface coal mining.

|

Staple Size |

Belt Thickness Range |

Max Breaking Tension of Belt |

Max Working Tension |

Min Pulley Diameter |

|||

|

NO. |

Inch |

mm |

PIW |

mm |

PIW |

Inch |

mm |

|

24 |

.31 – .39 |

8 – 10 |

15,000 |

2625 |

1500 |

20 |

500 |

|

26 |

.39 – .47 |

10 – 12 |

|||||

|

28 |

.47 – .63 |

12 – 16 |

|||||

Twin staple fastener. Good for the deep troughed belts whose troughing angle is 45′.

Twin staple fastener. Good for the deep troughed belts whose troughing angle is 45′.

- Complete range: for the belt thickness 8-16 mm,

- Made of high strength steel: the strength, rigidity and wear resistance of the fasteners are guaranteed.

- The joints have a high strength and long life.

- The front edge of the fastener is chamfered which decreases the impact on idlers and beltcleaners.

- Easy installation for the fasteners by the lever style MiniMatic fixing tool,

Applications: Underground and surface coal

Twin staple fastener

Twin staple fastener

Good for deep troughed belts whose troughing angle is 45′

Complete range: for the belt thickness from 7.5 to 16mm

The “staggered” arrangement of the staples enables a splice with a high tensile and dynamic strength to be installed. The loads are spread across the “staggered” staple arrangement

The front edge of the fastener is chamfered which decreases the impact on idlers and belt cleaners

Easy installation of the fasteners is achieved by the hammer tool (T10H) or by the lever style fixing tooI (T10)

Applications:

Under ground and surface coal mining

Solid strip fastener:

Solid strip fastener:

One complete fastener strip is installed on the belt across the full width preventing fastener loss or damage during transportation and storage.

Single fastener size suitable for a wide belt thickness range:

RV6 can be used for a belt thickness of 6- 12mm, making the RV6 easy for the customers to manage,.

High strength of the joint:

The V shape of the staple arrangement enables a high density of staple penetration on the installation without causing damage to the core of the belt.

Good alignment of the joint:

The fasteners are installed with the hammer tool. Install the fastener on either side and in the center of the splice ensuring the fasteners are square to the belt and then install the fasteners across the full width. Because of the good alignment, it is very easy for the connecting pin to be inserted.

Less impact during the operation:

The V shaped low and flat plate fastener body with a chambered leading edge decreases the impact and wear to idlers, pulleys and cleaners during the operation of the conveyor.

Improved life of the pin:

The loop section of the fastener is designed to maintain a good even radius after the fastener is clenched, thus providing a good working surface for the connecting pin to interact with.

Applications:

Mining Construction, Asphalt plants, Aggregate plants

T-Series Fasteners

| Reference | Maximum PIW | Belt Thickness | Connecting Pin |

| 113103 | 2000 | 19/32” – 23/32” | 9mm pin required |

| Reference | Maximum PIW | Belt Thickness | Connecting Pin |

| 112181 | 100 | 13/32” – 9/16” | 7mm pin required |

| Reference | Maximum PIW | Belt Thickness | Connecting Pin |

| 116102 | 600 |

36” (900mm) 9/32” – 7/16” |

5.4mm pin required |