Depreux Underground Applications

Our Depreux fire resistant conveyor belts are intended for operation in underground mines excavating flammable and non-flammable minerals, in methane or non-methane areas, classified to “a”, “b” and “c” of methane explosion category and in the excavations classified to “A” and “B” of coal dust explosion hazard.

They meet high standards related to heat resistance, anti-static electricity and safety in accordance with MSHA in the USA. Which is confirmed with documents approving these belts for use.

These heat specifications meet international standards in:

- EN14973 in Europe,

- Stage Mining Authority (WUG) in Poland,

- VVUU Czech Republic, Ukraine.

Multi-ply

Polyester Straight Warp

Aramid Straight Warp

Solid Woven

Steel Cord

Depreux developed three types of muti-ply belts for underground applications :

Depreux developed three types of muti-ply belts for underground applications :

DELTAFLAM GT , GI , FIREWALL (MSHA approved)

The belt carcass is made from 2 to 5 plies and it ensures :

- high strength of vulcanized and cold glued splicing,

- high tear resistance,

- good flexibility and proper centering in the trough.

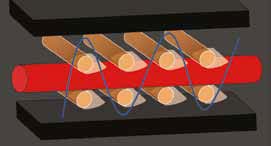

For polyster straight warp belt, we developed the Fireshield, also known as DX Flex.

For polyster straight warp belt, we developed the Fireshield, also known as DX Flex.

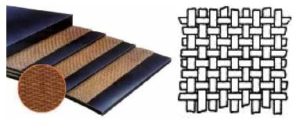

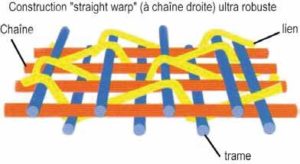

The carcass is composed of one or two plies of straight-warp, protected on both top and bottom sides by weft lines in textile as shown in the drawing to the right.

The carcass frame constructed is adhered RFL and may be coated with different types of rubber cover, anti- abrasive (X, Y, SH, etc).

Fireshield / DX Flex conveyor belting, is thinner in construction in order to reduce the minimum required diameter of the pulleys in the conveyor system.

Reducing the physical size of the pulleys making for easier installation—an advantage in restricted areas such as those often required in tunnel and mining applications. The smaller required sizes also reduce the costs of the pulleys.

Polyester straight-warp carcass has an alternative with an additional layer of aramid.

Polyester straight-warp carcass has an alternative with an additional layer of aramid.

DX-Flexamid belt is a straight-warp carcass combined with a layer of aramid straight chain fiber yarn, with two layers in the weft direction, upper and lower polyamide textile fiber yarn.

The main feature of this belt is that it is the lightest and the thinnest in all textile and steel options.

It acheives being the lightest and thinnest due to the aramid yarn composition.

Aramid yarn has 3 times more strength (or tenacity) than a polyester yarn for the same weight, and roughly three time less elongation.

Compared to steel construction, it is naturally much lighter and its elongation is in the same order of magnitude as steel.

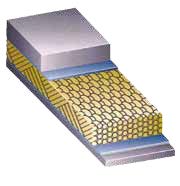

As for solid woven belt, we developed two variations of belt : PVC and PVG also known as Firemaster.

As for solid woven belt, we developed two variations of belt : PVC and PVG also known as Firemaster.

The FIREMASTER or PVG belts are made of a textile solid-woven carcass, impregnated with special PVC. The carcass is then protected with special anti-abrasion rubber (PVG belts) or PVC covers.

Main mechanical properties: The solid-woven textile is made of polyester (E) yarns in the warp direction to minimize the stretching of the belt, and of polyamide (P) yarn in the weft direction for good belt flexibility.

A major advantage over ply belts is that solid woven belts need smaller drum diameters.

The advantage over steel-cord belts is that PVG/Firemaster belts usually need less power to function.

Firemaster belts are also perfect for long distances and/or when they system faces a steep slope.

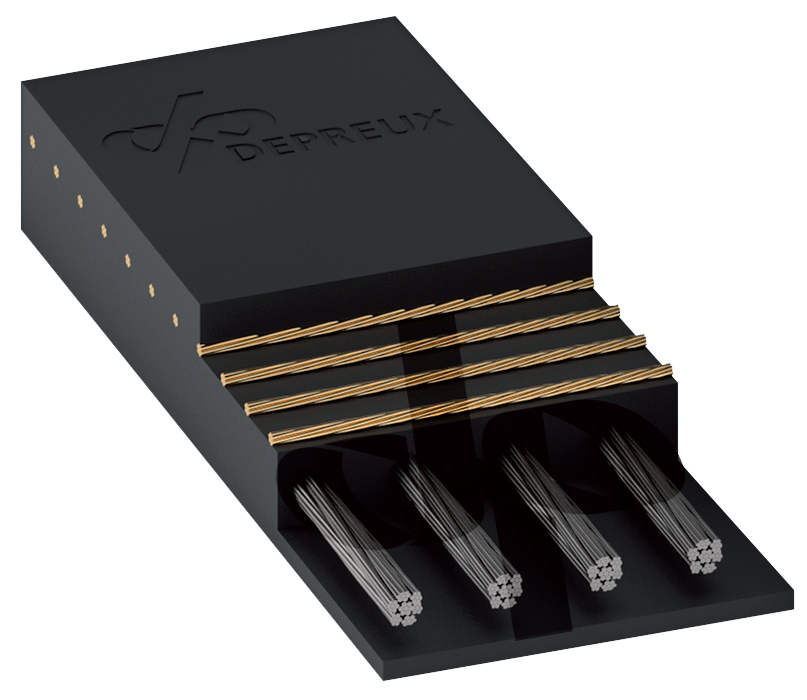

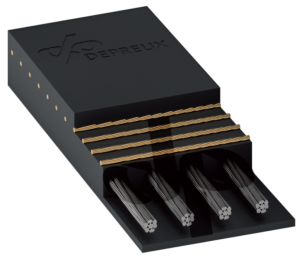

For steel cord belts, we developed the Firemaster ST. This belt is a MSHA approved belt.

This belt is composed of :

- Steel cables placed at a constant pitch across the width of the belt

- A special rubber-bonding layer to the cables and to the rubber covers

- Top and bottom rubber covers.

Steel cord belts are preferred to textile or solid woven belts in the following situations :

- When the required tensile strength is high and the conveyor is narrow.

- When a very low elongation of the belt is required.

- When the life expectancy for the belt is the prime objective.