TunnelMax

The TunnelMax conveyor belt has excellent tearing resistance and heavy impact resistance properties.

Due to the thinner carcass, TunnelMax can be used with smaller pulley diameters than textile plied or steel-cord belts.

TunnelMax’s ability to trough is much better than a plied conveyor belt. TunnelMax can also be joined with mechanical fasteners.

TunnelMax can be utilized on heavy duty conveyors where resistance to the effects of heavy impacts and tearing are important to the job.

TunnelMax belts are typically seen in quarrying, open cast mining and steel industries or in applications where heavy-duty and yet narrow belts are required, such as in tunneling.

For polyster straight warp belt, we developed the Fireshield, also known as DX Flex.

For polyster straight warp belt, we developed the Fireshield, also known as DX Flex.

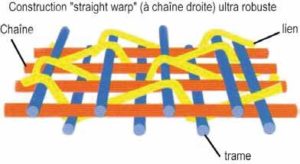

The carcass is composed of one or two plies of straight-warp, protected on both top and bottom sides by weft lines in textile as shown in the drawing to the right.

The carcass frame constructed is adhered RFL and may be coated with different types of rubber cover, anti- abrasive (X, Y, SH, etc).

Fireshield / DX Flex conveyor belting, is thinner in construction in order to reduce the minimum required diameter of the pulleys in the conveyor system.

Reducing the physical size of the pulleys making for easier installation—an advantage in restricted areas such as those often required in tunnel and mining applications. The smaller required sizes also reduce the costs of the pulleys.